Fluid Migration Mechanisms Due To Faulty Well Design and/or Construction

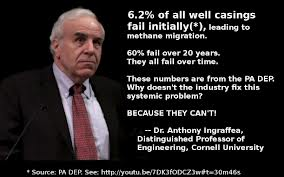

By Anthony R. Ingraffea, Ph.D., P.E., October 2012.

SUMMARY. See full paper “here.”

The most recent experience with shale gas wells in the Pennsylvania Marcellus play reflects long term, world-wide industry data with respect to new wells with compromised structural integrity. Operator-wide statistics in Pennsylvania show that about 6-7% of new wells drilled in each of the past three years have compromised structural integrity.

This apparently low failure rate should be seen in the context of a full buildout in the Pennsylvania Marcellus of at least 100,000 wells, and in the entire Marcellus, including New York, of twice that number.

Therefore, based on recent statistical evidence, one could expect at least 10,000 new wells with compromised structural integrity. It is too early to discern whether the other industry experience with this technical problem, an increase in loss of integrity with well age, will also be reflected.

However, at play in modern shale gas development are many of the key factors identified by industry researchers as having a negative influence on well structural integrity: the need for deviated wells, rapid development of a field, presence of “shallow” high-pressure gas horizons, and disturbance of young cement due to adjacent drilling activities on the same pad.

Display 1: 1,609 wells drilled in 2010. 111 well failures. 6.9 % rate of failure.

Display 2: 1,979 wells drilled in 2011. 142 well failures. 7.2 % rate of failure.

Display 3. 1,040 wells drilled Jan/Aug 2012. 67 well failures. 6.6 % rate of failure.

Display 4. Consistent with previous industry data, and not improving.

{ 2 comments… read them below or add one }

I see that 7% fail in the beginning and even more over time. So this in itself spells environmental disaster. I noticed cement quality is issue, this is because of the pH in the cement and viscosity. If you have a high pH this is hot cement and will set up faster, allowing more gas cuts and therefore migration. Some companies drill on fluid waterbased in the shallow zones. The idea is you have a larger diameter wellbore so gallon per minute and hydrostatic pressure can easily fracture formations/water aquifer.

I had seen volume losses to indicate downhole loss. When companies drill on air it is less pressure on formation and less differential effect in return. Due to the formational damage there is a need to squeeze cement but often at times this is neglected and the FIT test (formation integrity test) is often inaccurate at best.

Formation competency/integrity is the issue but, wells that are deviated due to multiwell pad go out 10 degree and back to avoid first well. therefor no FIT test is often done. With intermediate string often set at 2700 to 2900 then there is a lot of opportunity for formation damage because by the time you TD at around 13000 to 14500 you have had a psi of 4000 with all the GPM/hydrostatic head you can get via sweeps while drilling.

This is a lot of pressure, friction, GPM, to endure until long production string is ran. The formation integrity, porosity, etc. all seem to be a concern. You would see gas cuts on cement bond logs and migration could begin before the production string is in. There is a lot to look at and no regulation to help. We can not allow these companies to put our living standards aside for the sake of production and profits.

A big concern that has not been addressed here in WV is the fact that the industry is planting most of these Marcellus well pads less than 2,000 feet from conventional wells. Hard not to do when there are 59,000+ conventional wells in WV.

Many of those old wells aren’t even recorded in WV DEP’s database. And many of them have shoddy or no casings at all.

When the fracking is done on these Marcellus wells, inevitably they will “communicate” with these nearby shallow, conventional wells. You can’t send water, sand, and chemicals via extremely high pressures, (10 -15,000 PSI) down these well bores and not expect it to disturb the surrounding ground in the vicinity. And that is what will cause contamination to leach into the ground water and jeopardize the aquifers in addition to the realization that all well casings will eventually fail.

The industry is short-cutting the curing time on these cement jobs also. Time is money for them. With little oversight, it is doubtful that these cement jobs are done to perfection. Inevitably many will be compromised.

Consider that, along with the fact that they are next to these 50-100 year old abandoned wells (drilled before there even was an EPA to set standards) and you now have a recipe for disaster. And the industry surely realizes that, but won’t acknowledge it to the public.