From An Article of Petrochemical Updates, London, UK, September 19, 2018

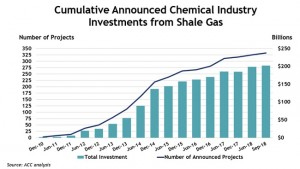

U.S. chemical and plastics industry investment linked to natural gas has now surpassed $200 billion, the American Chemistry Council (ACC) announced in September.

Since 2010, 333 chemical industry projects cumulatively valued at $202.4 billion have been announced, with 53% of the investment completed or under construction and 41% in the planning phase.

Fully 68% of the total is foreign direct investment or includes a foreign partner. Project types include new facilities and capacity expansions.

“This is an exciting milestone for American chemistry and further evidence that shale gas is a powerful engine of manufacturing growth,” said ACC President and CEO Cal Dooley. “The U.S. remains the most attractive place in the world to invest in chemical manufacturing. We look forward to continuing to transform energy into a stronger economy and new jobs.”

ACC analysis shows that $202.4 billion in capital spending could lead to $292 billion per year in new chemical and plastics industry output and support 786,000 jobs across the economy by 2025.

A note of caution is in order however, the ACC warns.

U.S. manufacturers often rely on inputs that are not available or made in the U.S. to create products that cost less yet perform at the high level downstream customers expect.

“Protectionist trade policies such as tariffs and quotas unnecessarily raise the costs of those inputs, deter innovation and economic growth, and could ultimately weaken our country’s competitive advantage,” the ACC said.

########################

$$$. US-China trade war escalates.$$$

From an Article of Petrochemical Updates, London, UK, September 19, 2018

Hours after President Trump announced the third round of U.S. tariffs on $200 bn in Chinese imports, China responded with its own levies of up to 10% on $60 bn worth of U.S. products.

The U.S. tariffs start at a rate of 10%, before rising to 25% at the end of the year. They come into effect on September 24 and will apply to thousands of Chinese products.

China will also impose its tariffs on more than 5,000 items on September 24.

The third U.S. list includes a total of 1,363 chemicals and plastics products, of which the U.S. imported $12.9 bn worth from China in 2017, according to the American Chemistry Council (ACC) and International Trade Commerce (ITC) data.

The latest list from the U.S. excludes some key chemicals after trade groups rallied to remove them.

The U.S. did not include rare earth elements. China is the world’s largest producer of rare earths and the biggest supplier to the U.S., according the U.S. Geological Survey.

Rare earth elements and minor metals have broad applications in U.S. industry, ranging from jet engines to mobile phones to oil and gas drilling.

These materials are critical raw-materials that are used to make catalysts for fluid-catalytic-cracking (FCC) units, which are used in refineries to produce gasoline and refinery-grade propylene (RGP).

########################

$$$.China’s Sinopec plans to build Canadian refinery.$$$

From an Article of Petrochemical Updates, London, UK, September 19, 2018

China’s Sinopec Corp has joined a group planning to build a bitumen upgrading and petrochemical refining facility in Alberta. Using approximately 167,000 barrels of diluted bitumen per day, the facility will produce a broad range of products for domestic and exporting consumption.

In addition to Sinopec, the group includes an Alberta indigenous group, China State Construction Engineering Corp, and Alberta management company Teedrum.

Teedrum, an Edmonton based company, working in partnership with the Alberta First Nations Energy Centre (AFNEC) will lead the development.

Gasoline, jet fuel, diesel fuel and basic chemicals will be shipped across Canada and to markets in the U.S. Northwest via existing clean product pipelines, rail, and to deep water for export, the project’s consulting firm Stantec said in a statement.

The SinoCan Global refinery would cost C$8.5 billion, with a financing plan still to be worked out, according to Teedrum, which is an Edmonton based company, working in partnership with the Alberta First Nations Energy Centre (AFNEC) to lead the development.

The Alberta First Nations Energy Development fund will hold equity ownership in the facility generating revenue to support social and economic initiatives in Indigenous communities. Sinopec and China Construction will provide the expertise and investment needed to develop the facility.

The group hopes to receive regulatory approval from the Alberta and Canadian governments within two years.

{ 1 comment… read it below or add one }

U.S. refiners face emerging glut of fuel

From an Article by John Kemp, Reuters News Service, September 20, 2018

LONDON (Reuters) – U.S. refiners have processed a record volume of crude in the last three months, reversing the previous shortage of distillate but leaving the country with record gasoline stocks at the end of the summer driving season.

Fuel availability has been helped by the absence of a direct hurricane hit on the major refining centers located on the coasts of Texas and Louisiana, in stark contrast to the refinery closures caused by Hurricane Harvey in 2017.

Refiners have carried on processing at elevated rates well after the end of the normal summer driving season and into September in order to rebuild previously depleted distillate stocks (tmsnrt.rs/2MKZGBz).

But the now-plentiful supply of gasoline and to a lesser extent distillate implies refiners will have to cut processing more sharply than usual over the next couple of months to avoid creating a glut of refined products.

U.S. refiners processed 17.4 million barrels per day (bpd) of oil in the week to Sept. 14, up from 15.0 million bpd in 2017 (impacted by Hurricane Harvey) and 16.6 million bpd in 2016.

Refiners produced a seasonal record 5.5 million bpd of distillate last week, up from 4.5 million bpd in 2017 and 5.0 million bpd in 2016, according to the U.S. Energy Information Administration.

Distillate stocks have risen to 140 million barrels up from a recent low of just 114 million barrels in mid-May (“Weekly Petroleum Status Report”, EIA, Sept. 19).

Distillate inventories are now just 6 million barrels below the 10-year average compared with a deficit of 25 million barrels as recently as July 20.

Distillate availability has been improving significantly over the last eight weeks after deteriorating more or less continuously since the start of the year.

But the consequence of heavy refining activity to produce distillate has been the emergence of a potential over-supply of gasoline.

Gasoline stocks remained plentiful throughout the peak summer driving season and are now at a record for the time of year.

Gasoline inventories stood at 234 million barrels at the end of last week, up from 216 million at the same point in 2017, 227 million in 2016 and a 10-year average of 215 million.

Refiners use the shoulder season between the end of summer driving demand and the onset of winter heating to undertake scheduled maintenance and change refinery configurations.

Crude processing typically declines by almost 1 million bpd between the middle of August and early October, before starting to pick up again from the start of November.

But this year the decline may need to be deeper and/or longer than average, otherwise the market will head into the year-end with too much fuel, especially gasoline.

https://www.reuters.com/article/us-oil-prices-kemp/u-s-refiners-face-emerging-glut-of-fuel-kemp-idUSKCN1M023Q